- -Able to understand how to check the quantity and quality of stock received.

- -Able to understand a system of stock rotation.

- -Able to understand stock level maintenance and stocktake.

-

Receiving and Storing Stock

Click on the Play button to start the introduction video.

-

Show Me

Show Me

Receiving Stock

- 1. Check the invoice against the order book.

- 2. Check to make sure nothing is damaged.

- 3. Pay particular attention to the perishables in regard to quality - check the USE BY date

- 4. Count the number delivered - does it match the invoice?

- 5. Some items need to be weighed to make sure the right amount has been delivered

- 6. Check the order book again.

- 7. Not enough delivered? - quantity discrepancy

- 8. A product smells 'off' - quality discrepancy

- 9. Make a note of the discrepancies on the invoice and the order book

- 10. Let the supplier know of any discrepancies

Show Me

First In First Out (FIFO)Click on the Play button to start the video.

First In First Out (FIFO)

- FIFO stands for 'First In First Out'

- When we receive stock we need to rotate it - this method is called FIFO - First In First Out

- The FIFO method is especially important for products that could spoil or exceed their USE BY date

- Use foods in the order that they were delivered

- When storing food, older stock comes to the front to be used first, newer stock goes to the back

Show Me

Stocktake and Stock LevelsClick on the Play button to start the video.

Stock Items are called inventory. An Inventory System records the current amount of stock and its value.

The Periodic Inventory System

- Stock items are counted periodically - this is called a stocktake.

- The count and value of the stock are recorded.

The Perpetual Inventory System

This system gives:

- a continual record of stock and cost

- a running balance of all stock kept on hand

- as stock is received, the balance on hand is adjusted.

This system:

- is deemed to be the most effective

- is sometimes known as Bin Cards.

In order to minimise costs, it is necessary to minimise stock on hand.

There are two possible methods of maintaining stock levels: Par Stock Levels and JIT Stock Maintenance.

Par Stock Levels:

- are those amounts of stock kept on hand to satisfy the immediate needs of the establishment

- cover the lead time required for new stock to arrive

- allow for unforeseen circumstances

JIT Stock Maintenance:

- stock is ordered and received "Just In Time".

- JIT reduces stock on hand and expenditure.

Stock Storage

Correct storage is essential to minimise wastage and spoilage.

When spoilage or wastage occurs it should be documented and reported to your supervisor.

Stock Level Maintenance:

Maintenance level of stock can be difficult due to:

- the lead time from order to delivery

- the seasonal availability of produce

- transport

- cost variations

There are four issues critical to the effective management of stock:

- the levels that should be held

- the size of the stock orders

- how often inventory items should be ordered

- the care necessary to control stock.

-

Say It

There are 2 parts in this section.

1. The GlossaryThe glossary lists the more difficult words related to the topic in alphabetical order. The glossary also gives the meaning for each word.

2. Look, Cover, Write, Check!This activity gives you practice at remembering and writing the words from the glossary.

The Glossary

-

Do It

Jump to Activities

Jump to Activities

Do It: Receiving Stock

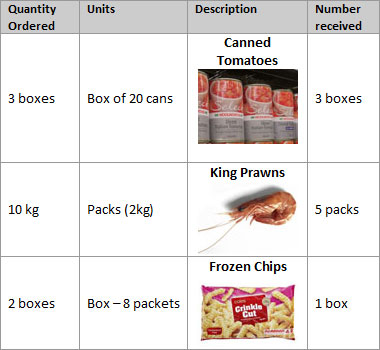

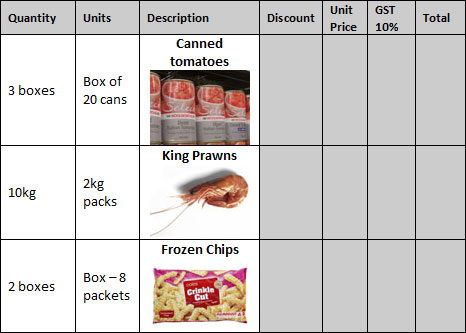

When goods are received it is important to check the amount received against the amount ordered. If these do not match, there is a quantity discrepancy. If goods received have been spoiled or damaged, this is a quality discrepancy.

Stock Order Forms or Books, and Invoices, are used to record orders and deliveries. These act as a check between the business receiving the goods and the supplier of the goods. Whenever there is discrepancy in quantity or quality this must be recorded and reported to your supervisor or supplier.

Sometimes inferior or incorrect goods are supplied instead of the ones on the Order Form and Invoice. If you receive inferior or incorrect products, this must also be recorded and reported to your supervisor or supplier.

-

Do It: Stock Rotation

Stock rotation minimises waste and maintains quality of perishable products. It is important to understand and follow the procedure used in your workplace.

The FIFO (First In First Out) method is used in many establishments and is especially relevant to perishable items. When storing food with the FIFO method, older stock is moved to the front to be used first, and newer stock goes to the back.

Do It: Stock Level Maintenance & Stocktake

Check It

Check It QuizStockClick on Stock to begin.

- Introduction

- Show Me

- Say It

- Do It

- Check It

Choose the best answer:

Choose the best answer: How many cans of tomatoes should be delivered?

How many cans of tomatoes should be delivered?